Production Technology

The right technology for your specific needs

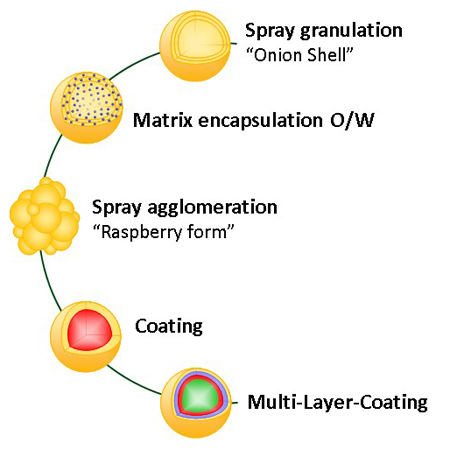

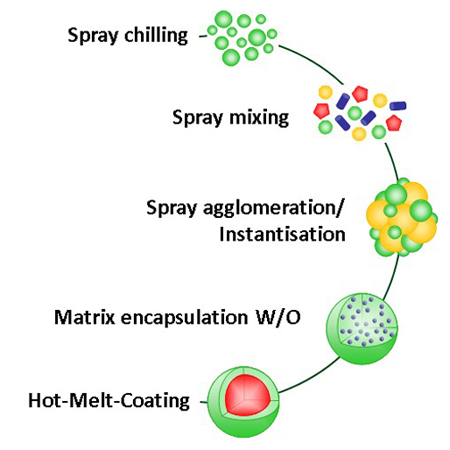

TriPlant, as part of the Erbo Group, offers a comprehensive range of production technologies. These include pre-mixing, liquid absorption on carriers, matrix encapsulation, granulation, spray chilling, coating, and extrusion. Our facilities are well-equipped with various resources for processes and materials, enabling the development and production of innovative powder products with specific properties. We also have pilot-scale equipment for formulation and process development, allowing for small-scale production. New processes and products can be up-scaled in-house from small pilot to large industrial production to meet your needs.

Processes

Processes with hydro soluble substances

PP-Technology (PP-500 & PP-5)

Bottom-Spray-Spouted Bed

Process air temp. +30 to +230°C

Processes with fats and lipids

MP-Technology (MP-11 & MP-1)

Top-Spray-Fluidized-Bed

Process air temp. -20 to +70°C

Plants & Capacities

Processes with hydro soluble substances

- PP-Technology (PP-500 & PP-5)

- Bottom-Spray-Spouted Bed

- Process air temp.: +30 to +230°C

- Production capacity:

- Production plant: 300 - 1'100 kg/h - Size of production campaign

- Production plant: ≥ 10 tons

- Pilot plant: Small amounts (starting from 2 kg)

Processes with fats and lipids

- MP-Technology (MP-11 & MP-1)

- Top-Spray-Fluidized Bed

- Process air temp.: -20 to +70°C

- Production capacity:

- Production plant: 500 - 3'500 kg/h - Size of production campaign:

- Production plant: ≥ 10 tons

- Pilot plant: Small amounts (starting from 2 kg)